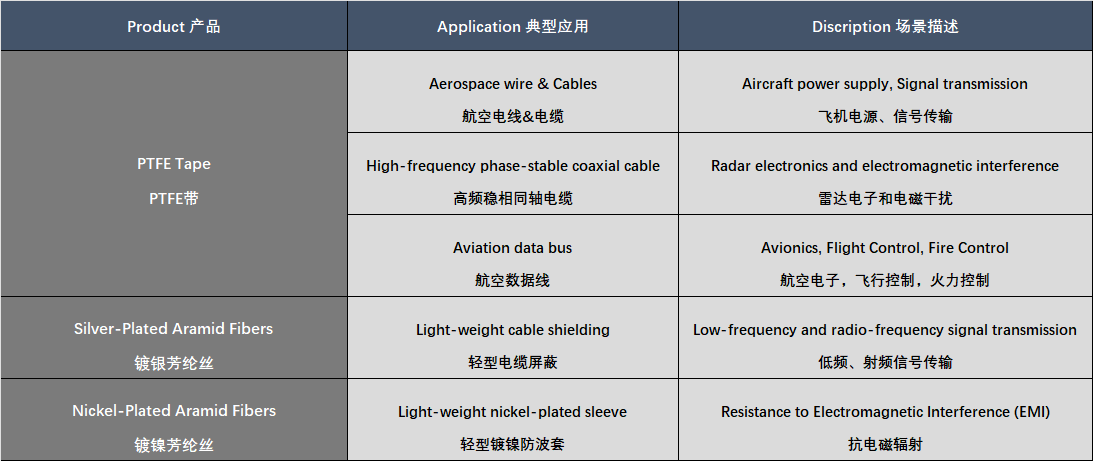

The Application of PTFE in Aerospace

PTFE tape, namely polytetrafluoroethylene tape, plays a crucial role in aviation cables, which is mainly reflected in the following aspects:

Insulation Protection

PTFE has excellent electrical insulation properties with a low and stable dielectric constant. It can prevent electric leakage and short circuits under different frequencies and temperatures, ensuring the stable operation of avionics equipment. Its good corona resistance enables it to withstand high voltages, helping the cables work reliably in complex electromagnetic environments.

High Temperature Resistance

The temperature around parts such as aircraft engines is high. PTFE tape can maintain stable performance within the range of -200°C to +260°C. It can withstand the heat generated during the operation of cables and the high-temperature environment, preventing damage to the insulation layer and ensuring that signal transmission is not affected.

Corrosion Resistance and Chemical Resistance

There are chemical substances like fuel oil and hydraulic oil in the aviation environment. PTFE tape has extremely strong corrosion resistance and chemical resistance, which can protect the conductors of the cables and extend their service life.

Low Friction Coefficient

PTFE has an extremely low friction coefficient. During the installation and use of cables, it can reduce the friction between the cables and other components, making the laying and maintenance of cables easier, reducing the wear of the outer sheath of the cables, and improving their reliability.

Aging Resistance and Radiation Resistance

Aviation cables need to be used for a long time and may be exposed to radiation such as cosmic rays. PTFE tape has good aging resistance and radiation resistance, which can maintain stable performance and ensure the performance and safety of the cables.

The Application of Metal coated aramid fiber in Aerospace

Silver-plated and nickel-plated aramid fibers play an important role in several key aspects of aviation cables:

1. Conductivity and Signal Transmission: Silver and nickel have excellent electrical conductivity. After being silver-plated and nickel-plated, aramid fibers can serve as the inner core or part of the shielding layer of the cable, enabling efficient current and signal transmission and maintaining stable communication between equipment.

2. Enhancement of Mechanical Properties: Aramid fibers originally have high strength and good toughness. Silver-plating and nickel-plating further enhance their mechanical properties, making the cables more resistant to stretching, bending, and abrasion, and prolonging their service life.

3. Electromagnetic Shielding: With good electromagnetic shielding properties, the shielding layer made of silver-plated and nickel-plated aramid fibers can not only resist external electromagnetic interference but also prevent internal signal leakage, improving the electromagnetic compatibility of the system.

4. Lightweight and High Temperature Resistance: Compared with traditional metal cables, silver-plated and nickel-plated aramid fibers are lighter in weight, which can reduce the weight of the aircraft and improve fuel efficiency. At the same time, they can work stably in high-temperature environments, meeting the special requirements of aviation.